History

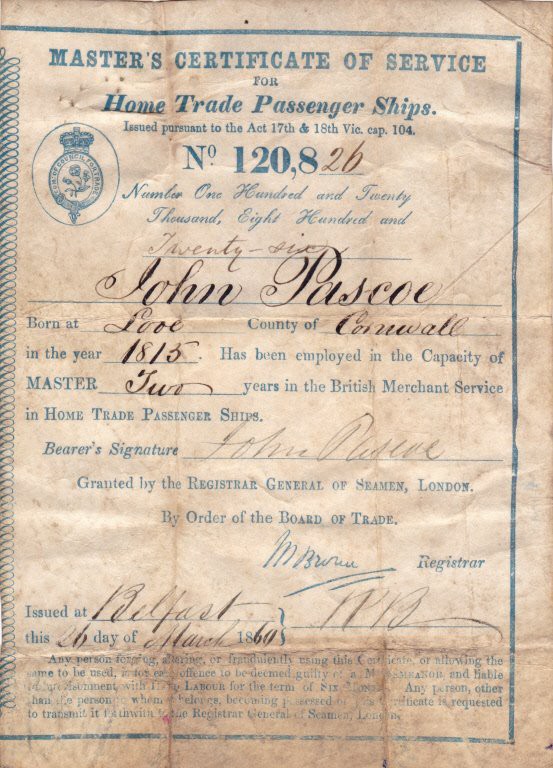

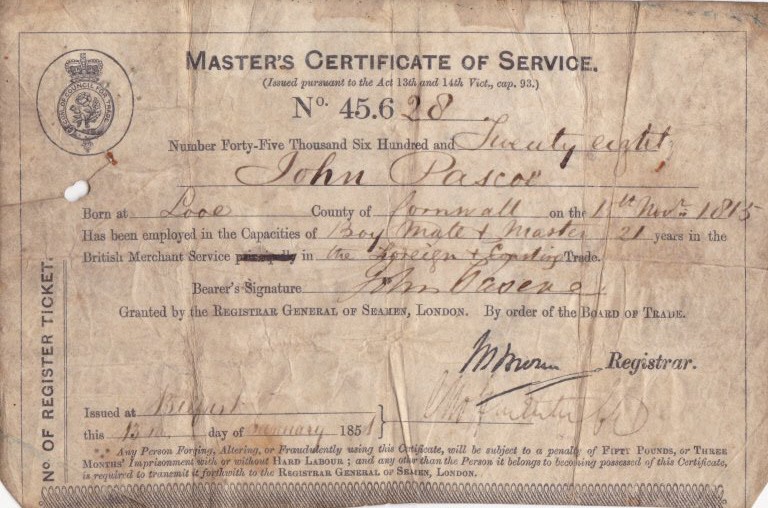

The Pascoe name has been connected with the maritime industry for a very long time, in fact before the first Pascoes arrived in NZ in the 19th century

The Pascoe name comes from Cornwall, southern England and is an area long known for its maritime history. Whether it be sailors in the Royal Navy, fishermen, coastal traders, boat and shipbuilders, or the illegal traders of goods sourced from the coast of France obtained by rowing across the English channel and back in the large gigs used to ferry out the pilots to the sailing ships entering and leaving the English channel. (A Cornish gig is a large rowing boat, approx. 28-32 feet long, rowed usually by 5 or 6 man with a man aft steering. These vessels were sometimes sailed as well).

It was in these maritime activities that many of these people were involved spending their entire lives right from an early age learning from and experiencing the sea and the associated activities whether it be boatbuilding, fishing or using the sea as a highway for trade. These skills have been handed down from generation to generation as a way of life, each generation experiencing something slightly different as the types of vessels changed and developed as they have done for hundreds of years.

Sam’s trade was a Brewer and he arrived with Jane and one child on the ship “Carisbrooke Castle “ 8th September 1875 along with other passengers on the ship after a voyage of 92 days from Belfast.

I believe they settled at Katikati with the promise of an allotment of land, as was common practice with the settlers at this time. This was never taken up and they moved to the Waikato.

Sam and Jane had 12 children one of which was my Grandfather Charles (my fathers’ father .)

Charles settled in Onehunga on the Manukau Harbour and that was where my father and his family grew up. At a very early age he went fishing on the harbour with his relations collecting scallops and catching the large snapper which the harbour is famous for.

I can remember Dad telling me that at an early age he became friends with an old scots shipwright who lived down on the edge of the harbour in a shack. He was known as “Chips Fordyce”. He repaired the wooden dinghies and wooden barges used for collecting sand on the Manukau. These barges were towed down the harbour with the tide, assisted by a launch with a single cylinder petrol engine, and beached. They then wheeled up sand onto the barge in a wheelbarrow and thus loaded the barge. It was then floated off and the return journey was assisted by the incoming tide.

Dad said the old fellow never liked children, but somehow he managed to strike up a friendship with him, sometimes helping him with his work.

I can also remember Dad telling me that Chips had been to China on the tea clippers, as a ship’s carpenter as a young man, and described vividly the large Chinese junks he saw. He was fascinated by these junks as they had the ability to beat to windward as do our modern day yachts, something a square rigger couldn’t do, that close to the wind.

For my father’s 10th birthday (1928) he was given a model yacht that was completed by his father. Chips carved the hull out of a solid block of Kahikatea. It was modelled on the Shamrock IV designed by Charles E Nicholson for Sir Thomas Lipton. At the time it was considered to be of a radical shape, with sawn-off ends and a very hard bilge. This model is 3 feet long (900mm) and what is known as a pond model.

At the time in Onehunga racing model yachts was a popular pastime, on what was known as Gloucester Park (now filled in by the motorway), a tidal area that was perfect for this to take place.

The long awaited anticipation of this model being completed caused my father being kept back a year at school. It must have been something really special to him.

I still have this model at home along with a slightly smaller one my dad built for me when I was a small boy, hollowed out of a block of Oregon pine off the base of a keel boat mast that had been repaired.

With the outbreak of World War 11 he was manpowered into the boatbuilding industry, it being classed as an essential service supplying small craft for the war effort. His employer was P Vos Ltd and one of his first jobs was to add onto the Vos shed to enable war contracts to be completed.

The first big contract was a 112 foot Fairey Marine “Fairmile”, of which two were built at Vos’s along with others built at Lidgards and Shipbuilders . These came with the frames and bulkheads pre-cut from 1 ¼” plywood to save the lofting process and hence speed up the build. The construction was 2 skin diagonal (no glue, calico and paint between the skins), over fore and aft stringers and the pre-cut frames and bulkheads. The total time taken was 6 months from start to completion for each vessel. I can remember Dad telling me they put the first complete skin on in a single day. Four gangs of eight men, started amidships, two gangs working aft each side and two working forward, plus two manning the steam box.

Among another things batches of “griping spars” were hand-adzed out of 2’-0” square Oregon flitches for use between the landing craft, barges and ships when alongside each other to keep them apart. (These spars were round and tapered at each end so that they rolled between the two vessels when alongside each other).

Among the men at Vos’s were members of some of the well known South Island boat building families that had come north to assist in the war effort – among them Barny Daniels who became a lifetime friend of my Dad.

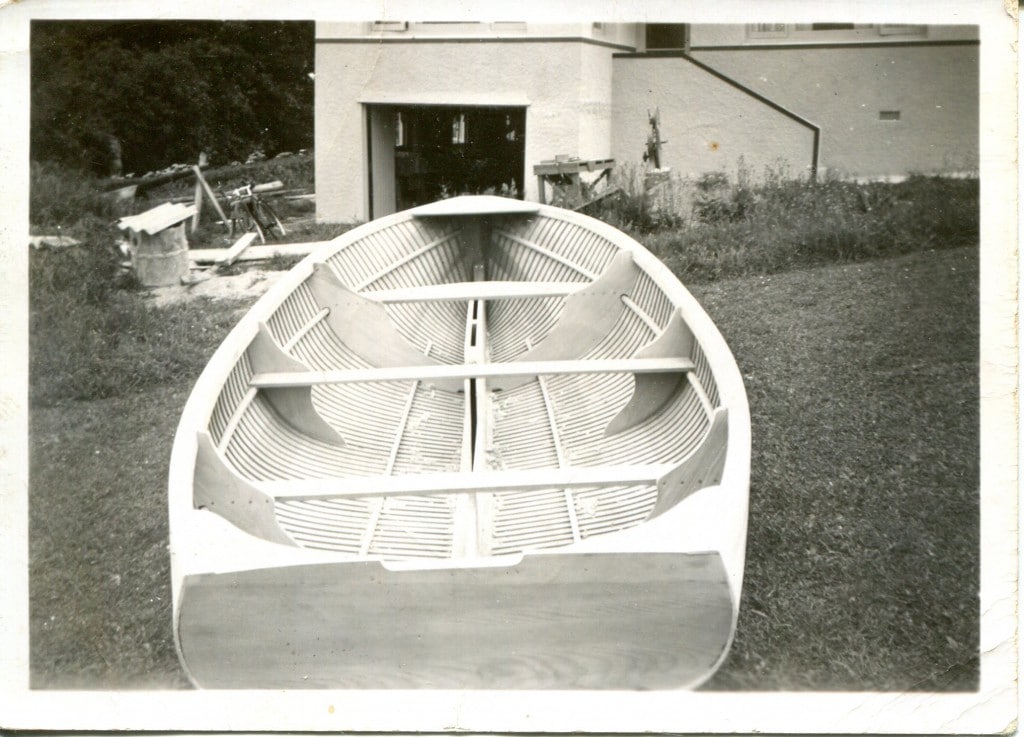

After the war ended another chapter started in Dad’s life and he went out house building with his brother, relegating boatbuilding to a hobby. During this time he built several 14 footers which raced in what was known as the “ T” class . These boats were different from the other T class and were somewhat similar to an English International 14 footer, except these boats were clinker built instead of multi skin smooth moulded like the International 14’s. His own boat was called the “Twilight “ and was built in 1948. I can remember this boat as a child as he brought it to Whitianga when he moved here in 1953 and kept for a number of years after that.

In 1951 the Result was shipped to Sydney to race in the Interdominion 18 footer contest.

The Result was then sold to Ron Watson who continued racing her.

In 1953 Dad and Mum moved to Whitianga which at that time was a small fishing village connected by the old Tapu/Coroglen Road to the outside world. Most of the goods came by the Coastal boat “Lady Jocelyn” which also shipped the butter from the local dairy company to Auckland. Mum’s parents at that time owned and operated the local bake house.

Dad had a number of jobs including working in the bake house & part-time boat repairs. In 1955 Dad built the family home and, shortly after that, built the workshop at Dundas Street. In the early days building work supplemented the boat repairs as well as building several small runabouts and numerous small dories for the fishermen.

In the late 50’s, once again doing something a little different, he built a 20 foot dory and called it the “Kaiwaka”. It was powered by a 3 hp Blackstone stationery engine, did 5 knots and a gallon of diesel lasted hours. She originally was all open with side decks, and later on a cabin was added and a repower undertaken to increase her cruising speed. The design incorporated a tunnel so as to decrease the draft for shallow water use. This vessel was basically a prototype for what would become the “John Dory”. The Kaiwaka did numerous voyages, including towing clinker-built sailing dinghies to the Cove at Great Mercury Island that he built for the Delamore family, who at that time owned Great Mercury Island in Partnership with Mizen Family.

Dories have been used for hundreds of years in fisheries in the northern hemisphere such as on the Grand Banks in the North Atlantic, in some of the worst conditions in the world. To convince them it was safe wasn’t easy to say the least, until someone with some sea experience arrived on the scene and then things began to get easier. The John Dory was eventually finished in 1970 and was issued with a coastal fishing survey. Now, 46 years later, my brother owns her, and she hasn’t capsized or drowned anybody like they predicted! She is in the Classic Yacht Association and everyone thinks she’s lovely. She attracts a lot of comments; good ones from people that know boats and dumb ones from people that know little about boats and the sea.

In 1973 I left school, my parents having paid for a good education at Mt Albert Grammer School in Auckland. I should have been an accountant, lawyer or doctor. I didn’t really know what I wanted to do apart from playing with boats. My first job was working for a bridge building contractor, Murray Speers Ltd who knew Dad and was based in Whitianga. The job was building the Carters Crossing Bridge at the bottom of the Tairua Hill.

I then managed to get a job working for Sealord Ltd on the box net project. This was for about 2 ½ years including working for other parts of their operation. I liked fishing but everyone told me it had no future so I then thought it would be a good idea to have a trade. As Dad didn’t want me to be a boat builder it looked like I had to do something else. I chose to be a diesel mechanic and served an apprenticeship at Industrial Steel and Plant, the then NZ Cummins agent. On completing my apprenticeship and gaining my trade qualifications I had had enough of living in Auckland. I moved back to Whitianga worked for Dad part time, assisting him to build a Chico yacht, and went fishing part time. I then worked for him full time assisting with repairs as well as the yacht.

While this was happening I learnt to fly, gaining my Private Pilots licence at the end of 1980. I then completed my Commercial Pilots Licence in mid 1982 while working with Dad. I had ideas of an aviation career and worked as a loader driver, but the jobs just weren’t there at that time so I figured I could come back to it if I wanted to.

In the beginning of 1983 I moved to Russell and got a job with Fullers. My stepfather had been badly injured in a car accident and I could then help Mum with things as she lived in Russell.

My job at Fullers was at the slipway, firstly as a mechanic and later on doing both mechanical work and boat repairs as needed. During this time I bought my Diamond class yacht “Starfire” and raced most weekends. The Bay of Islands is a good place to race as there are 4 clubs to choose from. I also raced on other boats when I got the chance.

In 1988, with the future of Fullers uncertain due to financial problems, I decided to move back to Whitianga and work back in the family business. In my time at Fullers I had furthered my skills as the company had been involved in marine painting, both on pleasure vessels and commercial vessels including steel and aluminium. These skills became more important as the trend was moving away from traditional wooden boats, both as pleasure boats and work boats, and painting became a more important part of the everyday operation of a boat maintenance operation with the advent of GRP and metal boats. The business name changed from H. Pascoe Boat Builder to H&M Pascoe Boatbuilders, a partnership between the two of us.

During the late 80’s onward the pleasure boat maintenance part of the business took over from other traditional boat building and repairs, and as the number of fishing vessels reduced due to the advent of the Quota Management System .

In the early 90’s I decided to formalise my Boatbuilding skills and sat Trade Cert and Advanced Trade Cert the following year. Under the old system this involved applying to the Apprenticeship Board and convincing them I had enough experience, and then actually sitting the formal written exams. I sat and passed the exams and the certificates are still on the workshop wall to this day. This was a proud moment as it was something I had wanted to do even as a small child.

With the opening of the Whitianga Marina in October 1995 and the associated hardstand, a new era for the business started. With the travel lift operating at the Marina larger vessels were able to be hauled and maintenance undertaken. With 191 berths in the Marina and the moored boats in the harbour there was a huge increase in the number of local boats. The emphasis of the business changed from the yard at 1 Dundas Street to the Whitianga Hardstand enabling the business to grow.

My then partner, now wife, Phyll came to assist me with the yard work as well as taking on the book work and administration. This was for a period of six years before devoting all her time to administration, as there was just not enough time to do both.

In 2005 the business became a Limited company .

In 2009 we took the big step of employing our first full time employee, Karl, who is a qualified boat builder with experience in building and fitting out composite pleasure boats and superyachts, and this advanced the capabilities of our business further. He is now also a qualified Marine Exterior Painter, having completed this apprenticeship with us.

Our next step forward was to employ a full time painter and that’s when Mattias arrived in 2011. He had extensive experience in the marine industry painting and fairing superyachts and bought this experience with him. Mattias has completed his apprenticeship with us and is now a qualified Marine Exterior painter, something he was already able to do but didn’t have the paperwork.

In 2017 we employed Scott Jamieson who has been a stalwart addition to the team ever since. He had done car painting while working for Toyota and wanted to learn marine painting. He completed a marine exterior painter apprenticeship with a lot of dedication and does most of the antifouls now.

The rest as they say is history. Even in my time since my first being involved in the boatbuilding industry as a child, and an enthusiastic observer assisting my Dad, the marine scene has changed dramatically in both types of design and construction. Some of these changes are for the better and I suppose some could be for the worse, depending on your point of view. The move away from wooden boats has come about through the lack of suitable durable timber and there is no denying that if you use an inferior timber the boat won’t have a very long life. Other newer methods have come along to replace the once plentiful timber supplies such as GRP and alloy. These products have their problems and as they say there’s nothing perfect in life.

It will be interesting to see what boats are like in another 50 years but I won’t be around to see it…

Mitch Pascoe